- The typical quality issues related with Ferro silicon can be described as follows:

- Si % lower than specified

- Dust, Slag or Slag inclusions in the finished metal

- Poor luster with dull and unfinished surfaces of the packed alloy

- Undersize

- Powdering or weathering of the finished alloy when stored and exposed to air.

- Uneven distribution of Iron and Silicon in the finished alloy

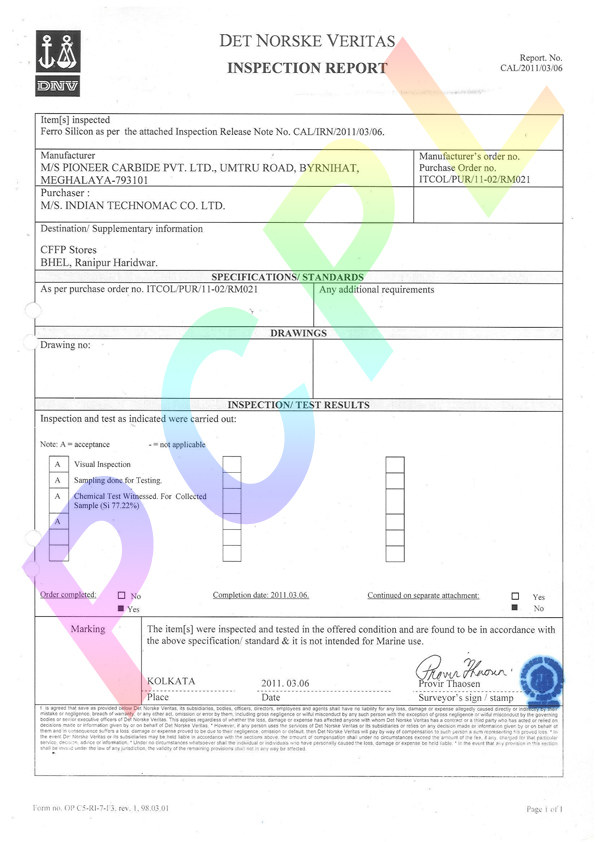

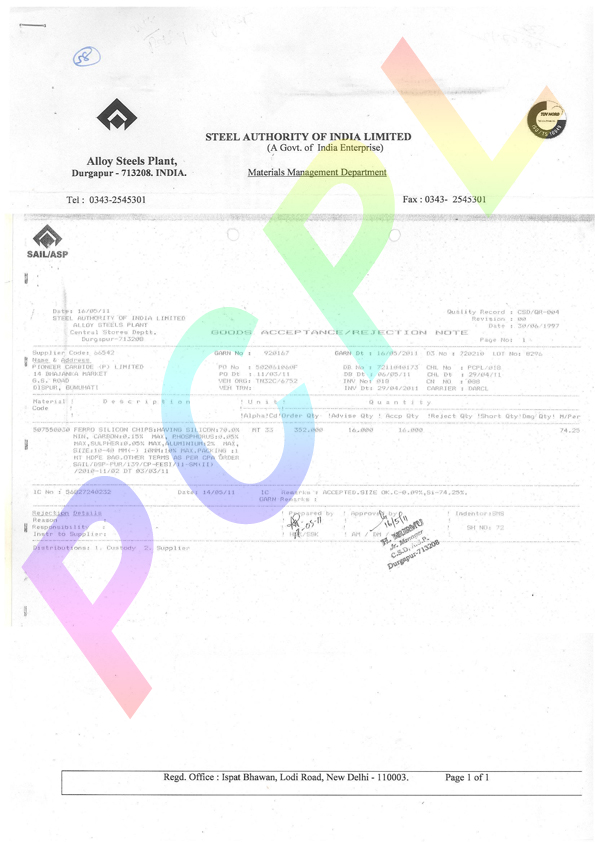

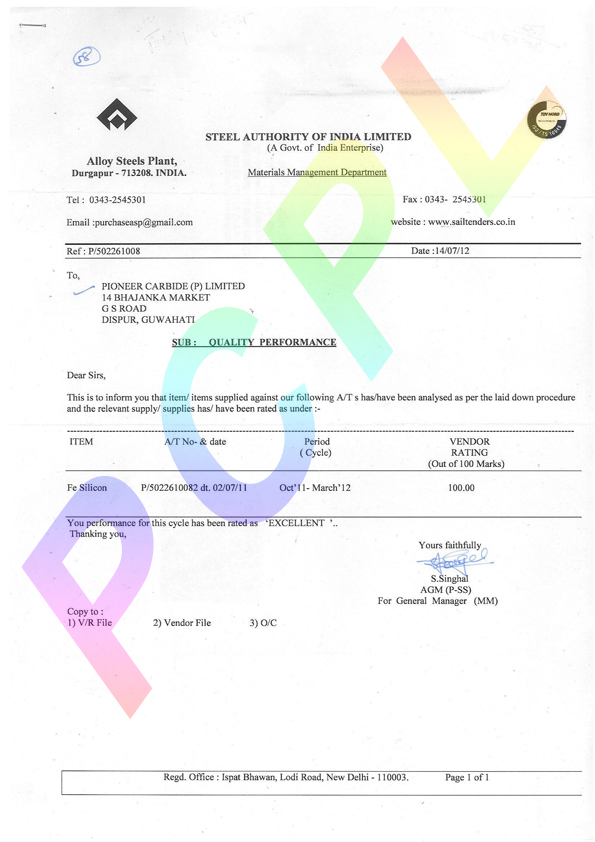

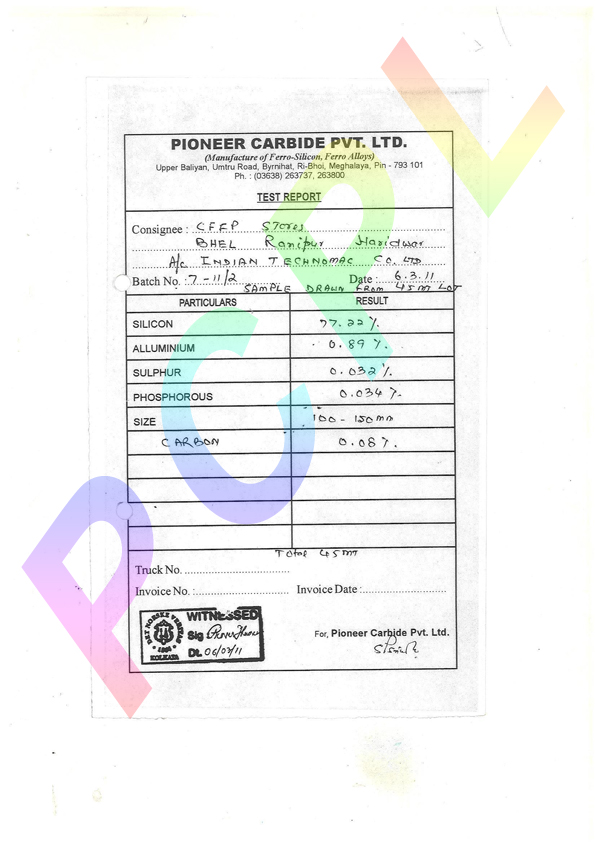

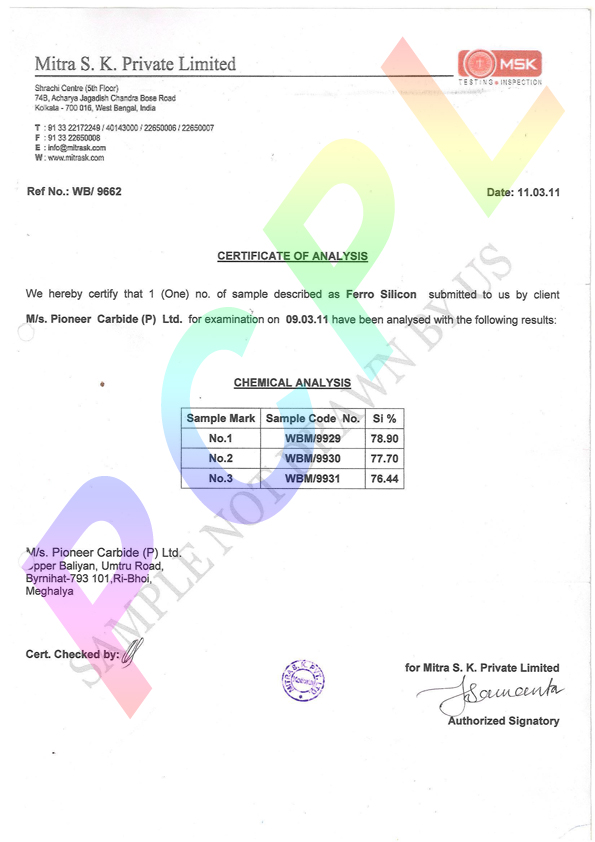

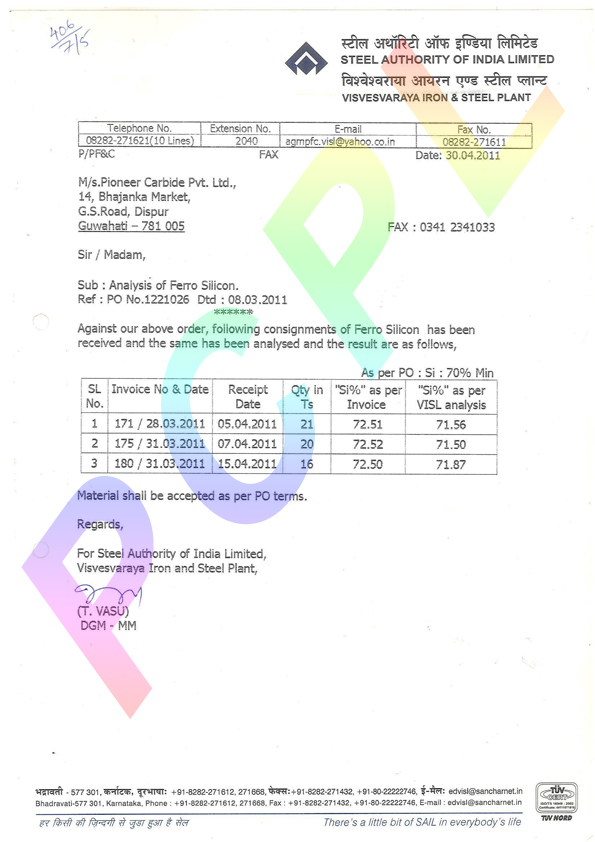

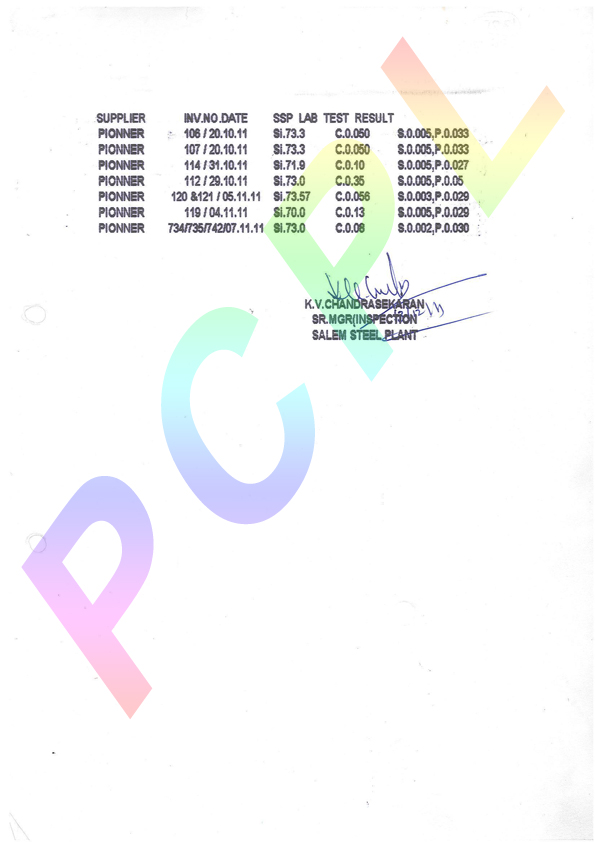

Pioneer Carbide offers Ferro Silicon free from any of the above defects. The company enjoys a solid reputation for quality products among its customers. The company has committed itself to quality by employing strict quality control measures for the raw materials as well as the finished Ferro silicon. Every tapping of Ferro Silicon is tested for its specifications and quality compliance. The finished Ferro silicon is compact, has smooth surfaces on sides, free from slag inclusions or dust and has a metallic sound when dropped on its heap.

Pioneer Carbide offers Ferro Silicon free from any of the above defects. The company enjoys a solid reputation for quality products among its customers. The company has committed itself to quality by employing strict quality control measures for the raw materials as well as the finished Ferro silicon. Every tapping of Ferro Silicon is tested for its specifications and quality compliance. The finished Ferro silicon is compact, has smooth surfaces on sides, free from slag inclusions or dust and has a metallic sound when dropped on its heap.Below are copies of documents, which outline the quality of Ferro silicon manufactured by the company